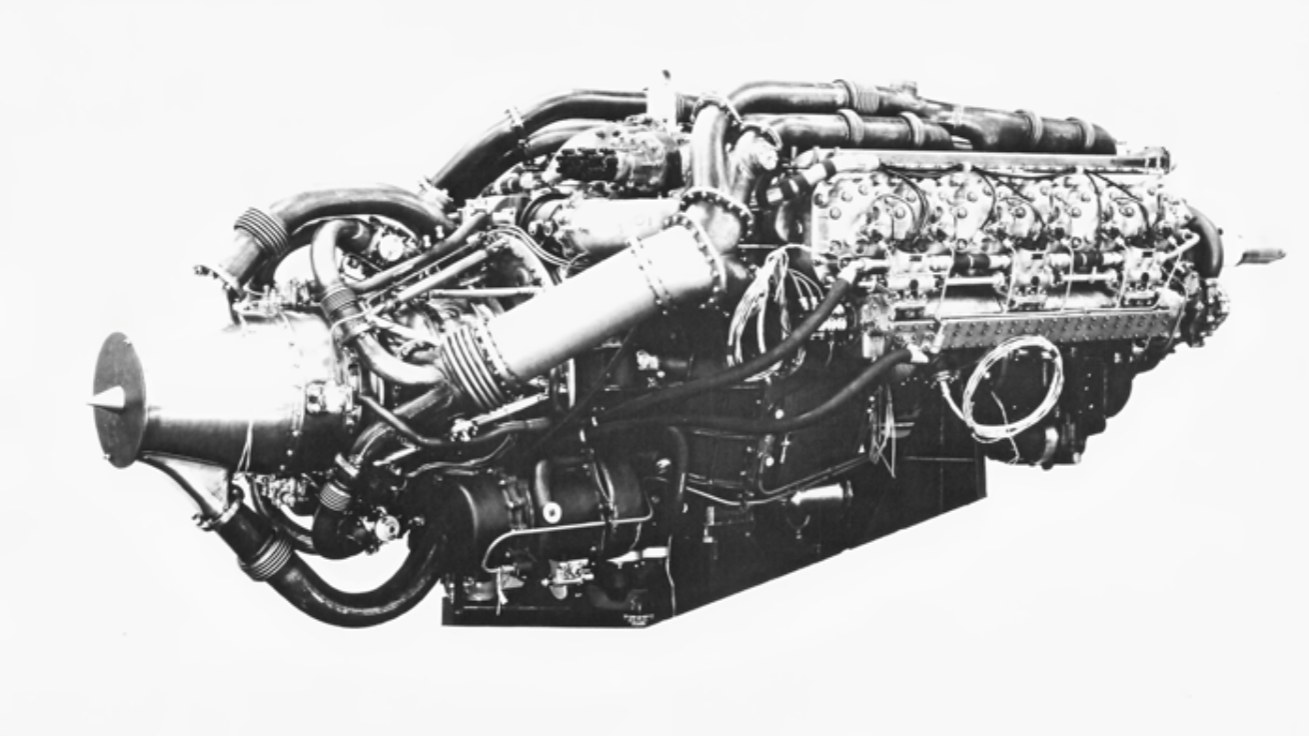

Was The Napier Nomad The Most Complex Aero Engine Ever Made?

From 1945 to 1955, a British aeronautical company called Napier & Son produced not just one but two versions of an intricate hybrid piston engine, which they named the Napier Nomad.

The post-World War II era saw the development of several fascinating (and highly complex) piston-powered aeronautical engines alongside the emerging gas turbine engine designs. During this period, gas turbines were inefficient, unreliable, and primarily used for military applications.

The (then) British Ministry of Supply commissioned the design and creation of a more fuel-efficient piston engine for aeronautical purposes, both military and civil, aiming to achieve gas turbine-like power while maintaining piston engine efficiency. Quite the challenge! The specification aimed for 6,000 hp and optimal fuel efficiency for long-range use.

Napier understood that gas turbines were limited by maximum operating temperatures, constrained by available materials, which increased fuel consumption and reduced range. Piston engines, on the other hand, operated at higher peak temperatures. This led them to consider combining both principles to create a superior design—a concept suggested by aeronautical engineer Sir Harry Ricardo, who had consulted for Napier on other projects.

Their complex solution was to build a gas turbine with a two-stroke diesel engine as the combustion chamber, merging the benefits of both. This liquid-cooled, horizontally opposed 12-cylinder two-stroke diesel engine featured a piston-ported design with shared crank pins arranged in a fork and blade configuration.

The two-stroke configuration vastly reduces pull loads on the connecting rods, allowing for lighter one-sided half bearings. The six-throw crankshaft ensured excellent primary and secondary balancing. The piston-ported design of the Nomad relied on a supercharger for efficiency, utilizing a crank-driven centrifugal compressor. Notably, a three-stage exhaust turbine also drove the same compressor shaft.

One propeller was gear-driven from the diesel engine, while the second, contrarotating propeller was powered directly from the compressor shaft through a second gearbox. It’s quite a unique machine!

To enhance take-off power, the engine was equipped with a kind of afterburner. This feature utilized a fuel injector in the exhaust of the diesel engine to increase the flow of exhaust gases, thereby generating more power for the turbine and providing additional thrust.

To maximize efficiency and extract every possible bit of power from the exhaust gases, a valve could be opened to direct some of these gases to a secondary exhaust turbine that operated alongside the main unit.

Despite the early optimistic power requirement, the Nomad I produced a total power of 3,000 hp, with an additional 319 lbf of usable thrust contributed by the exhaust turbine.

We won’t go into the second version of the (never constructed) engine, the Nomad II—you can watch the video yourselves for that. Suffice it to say, simplification was possible, with yet more innovation.

It’s a pity the whole program was cancelled and the engines never saw any usage beyond initial test flights.

If this engine sits firmly at one end of the complexity scale, then this DIY single-cylinder two-stroke surely sits at the other. And while we’re still thinking about piston engines, does anyone remember this neat free-piston engine?

*Images supplied by the Napier Power Heritage Trust.*

Thanks to [Stephen Walters] for the tip!

https://hackaday.com/2025/10/18/was-the-napier-nomad-the-most-complex-aero-engine-ever-made/